Let’s be honest—working with cement is messy. Whether you’re pouring a new driveway, repairing a warehouse floor, or tackling a DIY project, dried cement splatters and residue seem to get everywhere. A few weeks ago, I spent hours scrubbing my garage floor after a weekend project, and let’s just say my back hasn’t fully recovered. That’s when I realized: maybe I should invest in a proper cement cleaning machine.

You know what’s funny? Even professionals sometimes underestimate how much time they waste on manual cleaning. A buddy of mine runs a construction crew and joked that his team spends more time scraping cement off tools than actually using them. But once he got a dedicated cement cleaning machine, things changed. Suddenly, they could finish jobs faster, reuse equipment without hassle, and even take on more projects.

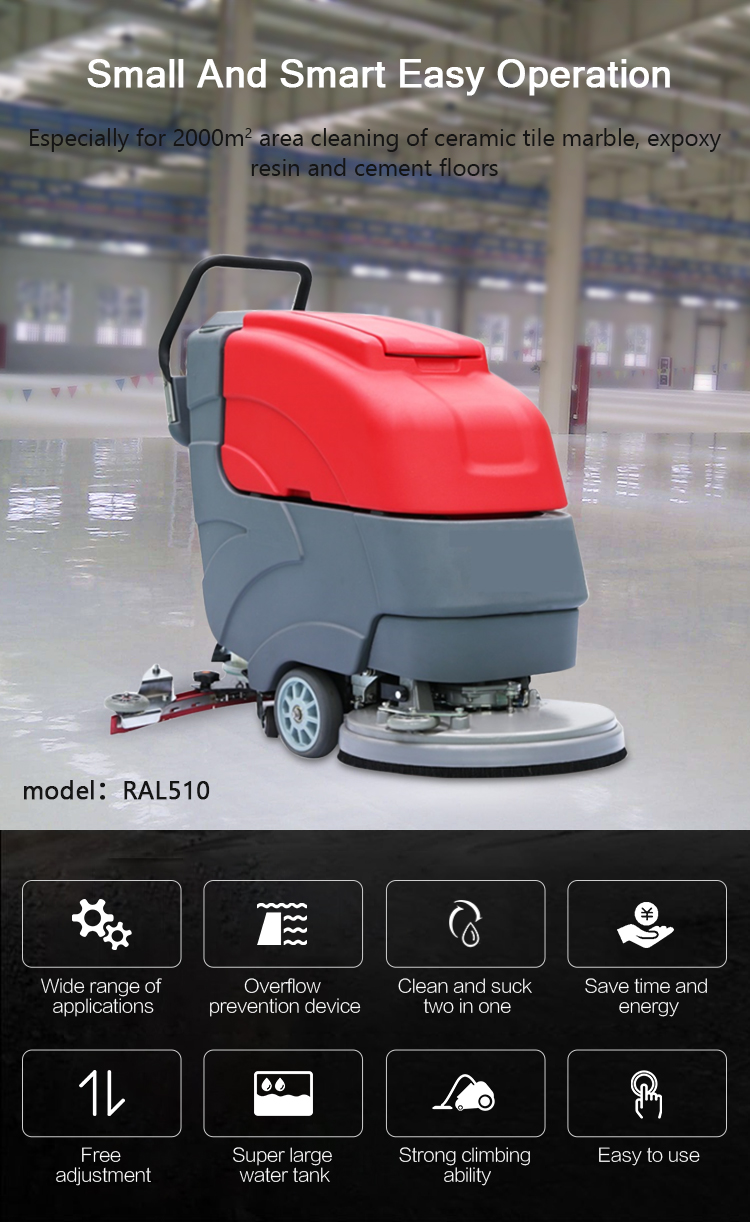

So, what makes a good cement cleaning machine? First off, power matters. You want something that can handle thick, dried-on cement without overheating. Look for motors with high RPMs and durable brushes. Portability is another biggie—dragging a heavy machine around a worksite is nobody’s idea of fun. Oh, and don’t forget adjustable pressure settings. A delicate tile floor doesn’t need the same treatment as a rugged concrete slab.

Maintenance is key too. After using your cement cleaning machine, always flush the system with clean water to prevent clogs. I learned this the hard way when mine sputtered out mid-job last month. Turns out, tiny cement particles had built up in the hoses. Rookie mistake, right? Now I keep a checklist: rinse, dry, check the filters. Takes five minutes but saves hours of downtime.

Speaking of downtime, let’s talk about efficiency. A quality cement cleaning machine isn’t just about brute force—it’s about smart design. Features like swivel handles make it easier to navigate tight corners, while ergonomic grips reduce fatigue. Some models even have built-in detergent tanks, so you can apply cleaning solutions on the go. No more stopping to mix chemicals in a bucket!

Here’s a random thought: why aren’t more people talking about the environmental benefits? Modern cement cleaning machines use less water than traditional methods, thanks to precision nozzles and recycling systems. That’s a win for both your water bill and the planet. Plus, efficient cleaning means fewer harsh chemicals down the drain.

I’ve noticed a trend lately—contractors are opting for electric cement cleaning machines over gas-powered ones. Quieter operation, zero emissions, and lower maintenance? Sign me up. Sure, they might cost a bit more upfront, but the long-term savings on fuel and repairs add up. And let’s be real, not smelling like exhaust after work is a nice bonus.

In the end, whether you’re a pro or a weekend warrior, a good cement cleaning machine is a game-changer. It’s one of those tools you don’t realize you need until you try it. Like that time I finally bought a decent coffee grinder and wondered how I’d ever tolerated pre-ground beans. Life’s too short for mediocre tools—and endless scrubbing.